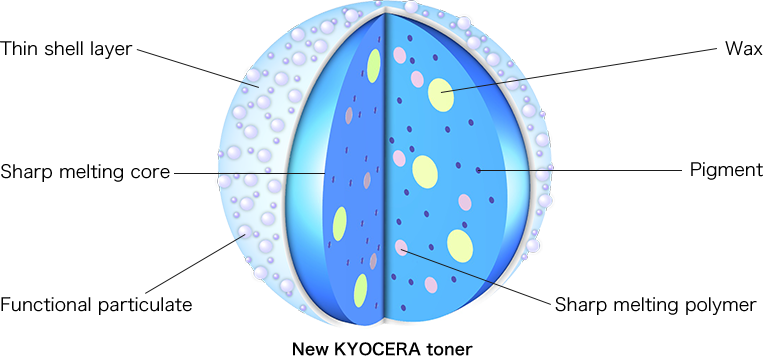

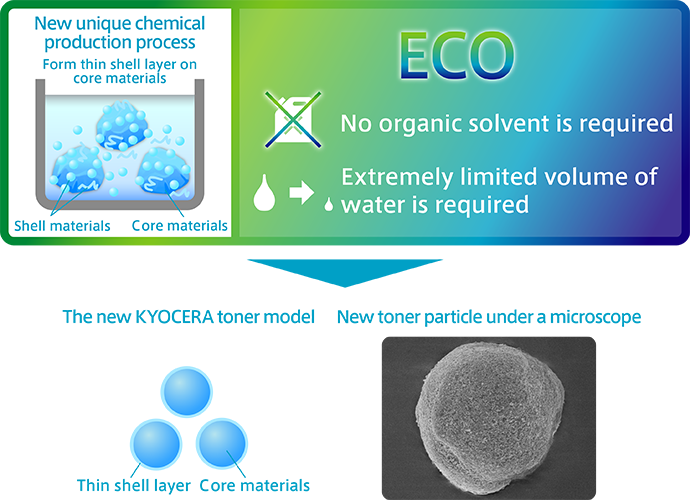

The new toner from KYOCERA has been developed by a unique production method.

The toner is structured with a thin shell around the sharp melting core.

This enables both low-temperature fusing and long-term stability, contributing to energy saving performance.

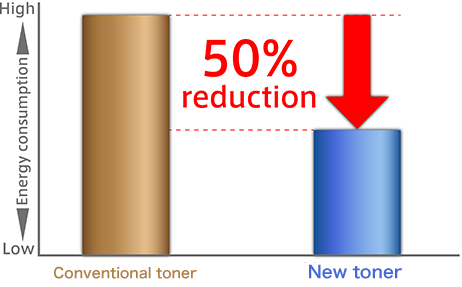

The toner fusing process consumes approximately 70% of the total energy consumption

in both MFPs (multifunctional products) and single-function printers.

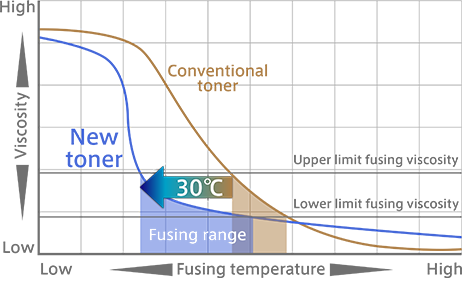

The new KYOCERA toner can fuse at 30 ℃ less than that of the conventional products.

As a result, the total energy consumption could be reduced up to

half with this toner compared to the previous systems.

he new KYOCERA toner has a thin shell outer layer produced by a unique chemical production process.

It is important to remember that no organic solvent and only a limited volume of water is required in this process.

Thus, KYOCERA is minimizing the environmental impact from the production process

all the way to the customer’s environment.

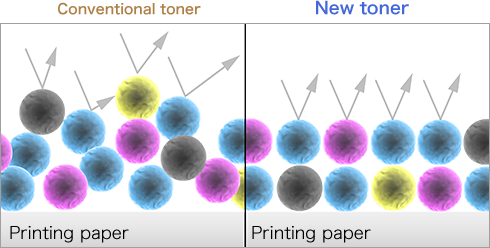

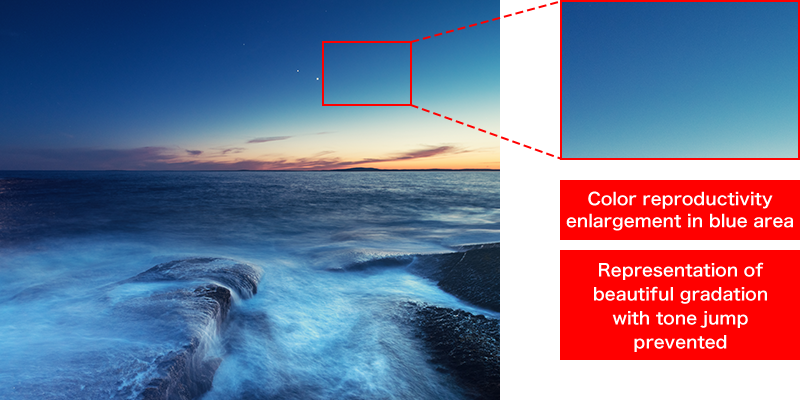

Smoother image representation is possible thanks to uniform toner layer forming.

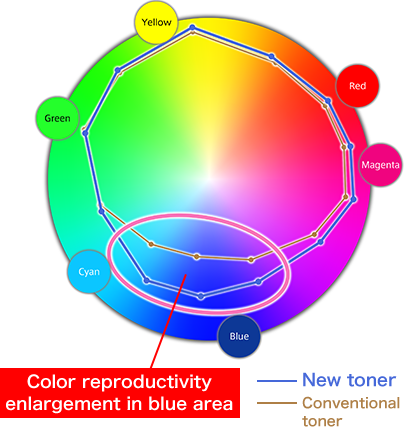

We could enhance colour reproductivity specially in cyan (blue) area, due to a change of toner colouring material.